Flat Slabs belongs to a two-way reinforced concrete slab that comes with without beams and girders. They are supported directly by columns and loads are transferred directly to the columns or load bearing walls.

The span of a flat plate floor is governed by the both the strength requirements and serviceability requirements represented by the deflection.

The function of this type of slab is to provide a plain ceiling surface, which will give the best diffusion of light.

Thickness of the flat slab is between 0.2m and 0.35m.

TYPES OF FLAT SLAB

Flat Slab

Flat Slab with drop panels

Flat Slab with column head/capital

Flat Slab with drop panel and column head/capital

Flat slabs are generally used in

- Parking garages

- Hotels

- Commercial buildings

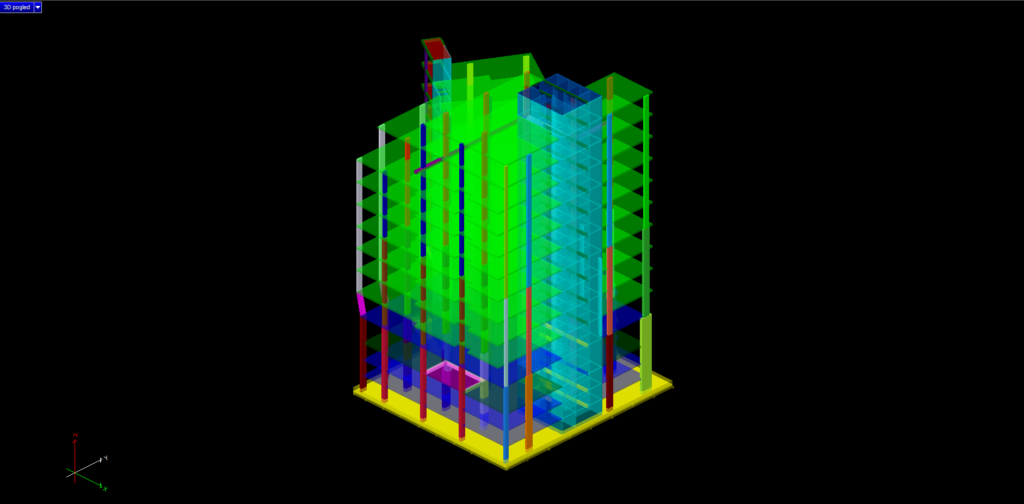

- High-rise buildings

- Industrial Structures

- Places where beam projections are not desired and where the need of aesthetics view.

Pros & Cons

Advantages

ADVANTAGES / BENEFITS OF FLAT SLABS

Flat Slabs provide huge benefits to the engineers as compared to other reinforced concrete floor system

Building height can be minimized

The height of the building can be reduced by minimizing floor to floor height as there is not beam and as a result the building height will also be decreased, thus reduces the cost of construction.

The floor gives a wide flexibility to locate the horizontal services such as mechanical ducts above a suspended ceiling / no obstructions to the building services.

No beams so you have the entire ceiling height available for all services.

It develops good Auto Sprinkler system.

Flexibility in the partitions. When the internal partition work is planned after the construction, it is much easier to plan them as there are no limitations by the beams.

Roughly 10% of the vertical member could be saved.

Foundation load will also be decreased.

Less construction time

Simple constructability, Simple formwork/Framework installation, as extensive large table framework is utilized, the construction time is minimized significantly and big saving in formwork.

Easy arrangement for Reinforcement

Flat slab can be easily arranged because of easy to follow straightforward reinforcement detailing.

A flat slab allows the use of a prefabricated mesh of standard size, requiring less installation and better quality control.

Reduce construction time.

Economical

The shear strength of the slab increased

Minimize the moment on the slab by minimizing clear or effective spacing.

Better appearance and offer better diffusion of light.

Better fire resistance than a conventional floor system

It offers faster construction and provides economy in the overall cost of the building.

DISADVANTAGES OF FLAT SLAB

It’s not used for large span design / Span Limitation / Covers medium spans

Not suitable for supporting masonry partitions in general

More suitable for lightweight partitions. An increase in the wall load could increase the cost of construction significantly.

Greater slab thickness is required as compared to typical RCC slabs

Use of drop panels may interfere with oversized mechanical ducting

Lower lateral load capacity compared to solid slab system

May need shear reinforcement at the columns to resist punching

Middle strip deflection may be critical

May not be suitable for heavy loads.

Third Edition Sept/Oct 2022

Technical

Author: Milan Zdravkovic

Civil & Structural Engineer