Authors : Solid Base

In the last edition we explained about the column and stages of checking the column were discussed in detail,

This month we are describing the beam, a horizontal element, which plays an important role of the structure

Factors affecting the quality management system in construction:

• Poor workmanship

• Poor Design

• Miscommunication between teams

• Failure to document changes and practices

A case study on one of the structural elements (beam)

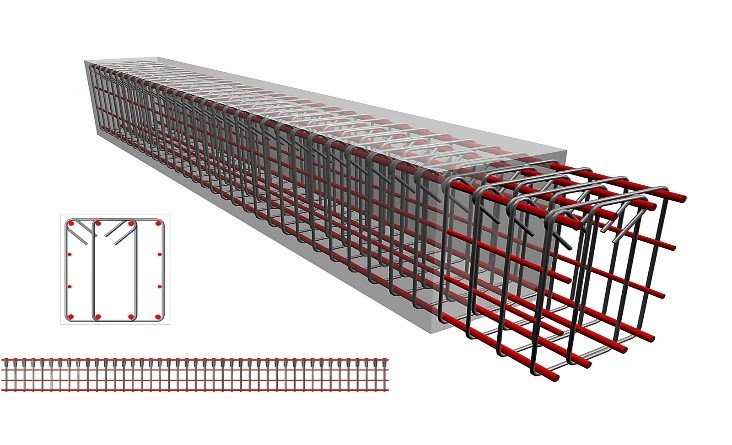

Fig A

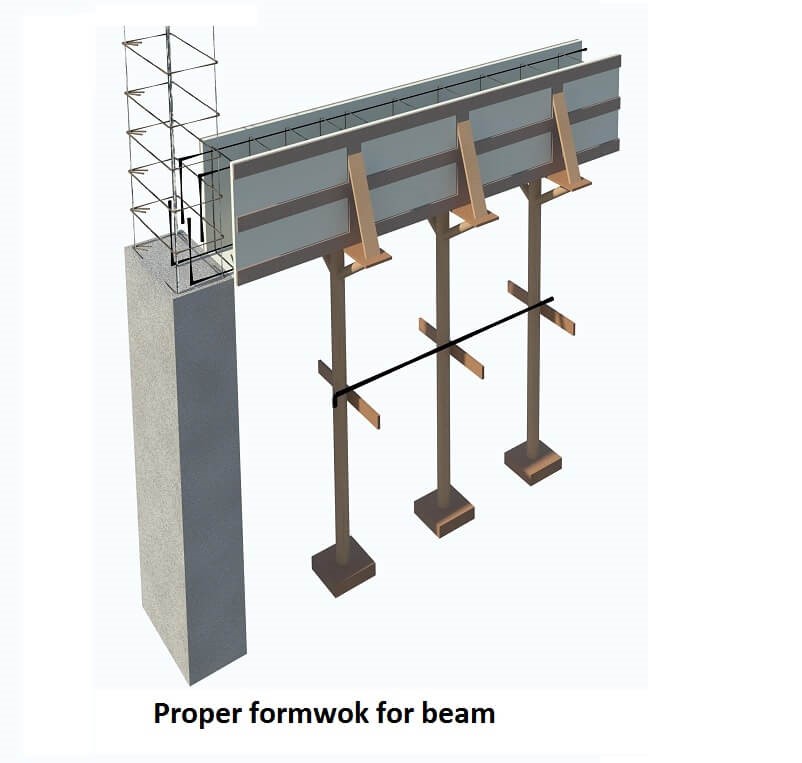

Fig B

A beam is generally a horizontal member which transfers the load of slab to column and to ground through footing five stages of Quality checking of the beam:

Ø Checking the beam layout and Centre.

Ø Checking the beam reinforcement

Ø Checking the beam shuttering

Ø Checking the beam concreting

Ø Checking the beam de-shuttering.

The reinforcement of the beam should be fixed and checked first, then the shutter be fixed.

Checks for reinforcement:

Ø The reinforcement steel should be free from any loose scale, rust or oil.

Ø Main bottom, top , side reinforcement and the Stirrups should be cut and bent as per the required length; this has to checked against the drawing.

Ø Dia, number of rebars and spacing should be checked against the drawing.

Ø Binding wires used should not protrude in the cover zone.

Ø Hook angles should be 135o this is very important from seismic consideration.

Ø Lapping should be provided in the central half of the member length and lap length should be 45D or as specified.

Ø Mill test certificate describing the physical and chemical properties of the steel.

Beam Shuttering:

Ø Shuttering should be properly aligned as per drawing and surveyor’s marking.

Ø Dimensions are to be checked against drawing.

Ø Shutter surface in contact with concrete should be clean, free from dirt, debris and other substances that may affect concreting or finished product.

Ø The gaps b/w the joints of shutter to be sealed to prevent the leakage of slurry.

Ø Cover should be minimum 40mm unless otherwise specified.

Beam concreting:

Ø Grade of concrete as per the design mix.

Ø Height of concrete Pour.

Ø Slump and temperature check

Ø Ensure the Vibrator is ready and in working condition and used for at least 30 seconds in each area.

Ø Excess water or superplasticizer was not added to concrete on site.

Ø The concreting is carried out within specified time period (90 minutes) from the batch time.

Ø Sampling of cubes for density & compressive strength testing.

Third Edition Sept/Oct 2022

Technical